OGM: UK plastic injection moulders

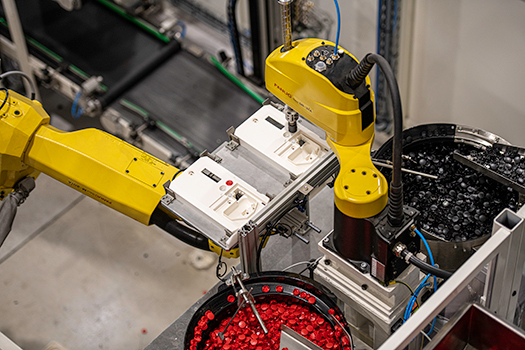

At OGM, we manufacture the highest quality plastic injection moulded parts and assemblies, using advanced injection moulding, automation and 3D printing technologies. We have the expertise and skills to help customers throughout industry reduce lead-times, while enhancing the quality, functionality and performance of injection moulded parts and components. We offer a full injection moulding service, including mould toolmaking, bespoke component assembly and finishing operations.

We are UK based plastic injection moulders providing you a full support through our two manufacturing sites in Oxfordshire and South Wales. Along with our plastic injection moulding, toolmaking and assembly services, we have the ability to offer added value services through dedicated project management and technical and customer support.

Plastic injection moulding

Our plastic injection moulding capabilities

We have over 92,000 sq feet manufacturing facilities, with 50 advanced injection moulding machines in our two UK manufacturing sites

Purpose-built injection moulding and product assembly facilities

Dedicated new product introduction (NPI) team

Class 7/10,000 cleanroom assembly areas providing the ideal environment for production of medical and electronics mouldings and components

Conventional injection moulding from a machine range of 35 to 1,100 tonnes

Elastomers and polymer injection moulded parts and components

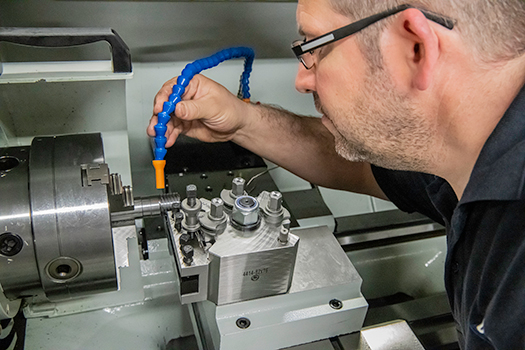

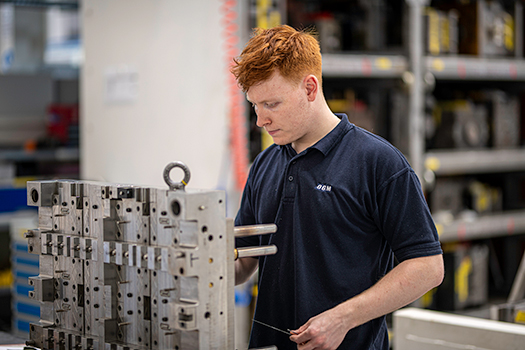

Toolmaking, with servicing, maintenance, repair and overhaul of existing tools

Injection mould tools

We have an extensive in-house tool-room, equipped with the latest technology and staffed by experienced mould toolmakers. Our tool-room ensures optimum tool availability, on-time production to plan and high service levels for every customer.

Toolmaking and tool design

Our tool making capabilities extend from soft prototype tools, through simple single impression P20 steel tools, to fully hardened steel multi-cavity full hot runner tools.

Injection mould tool inserts

Rapid production mould tools

How we help our customers

Plastic Injection Moulded Parts

Get in touch today to discuss your next project

UK's leading plastic injection moulding company

Offering complete solution for your plastic injection moulding needs

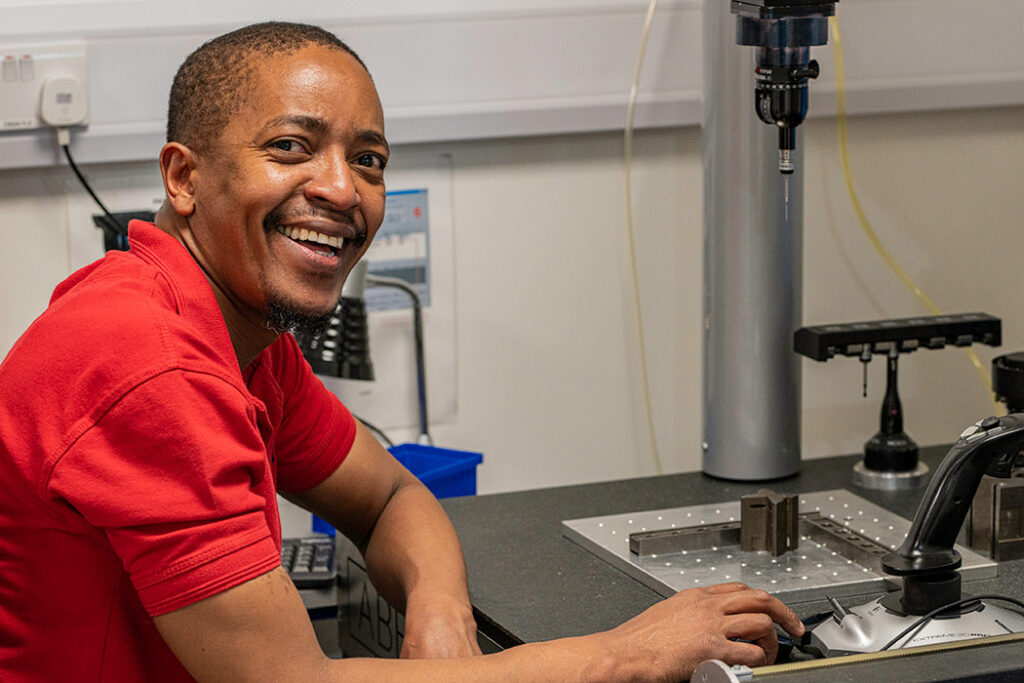

Quality

Vision