Post-moulding services

We offer a wide range of finishing services, some of which are part of our quality control and inspection process such as cleaning and leak testing and others, such as welding and heat staking, that we undertake during assembly. Other value-added services include EMC and RFI coating, sterilisation and product printing.

Protective coatings

Sterilisation

Welding and heat staking

Printing

Pad printing, also known as tampo printing, is used to transfer images onto a wide variety of complex 3D shapes and geometries using a silicone pad.

We have 4-colour pad printing for general industry applications and single colour printing within our cleanroom for printing on medical devices that are used both in and out of the operating theatre, in dental, orthopaedic and surgical applications.

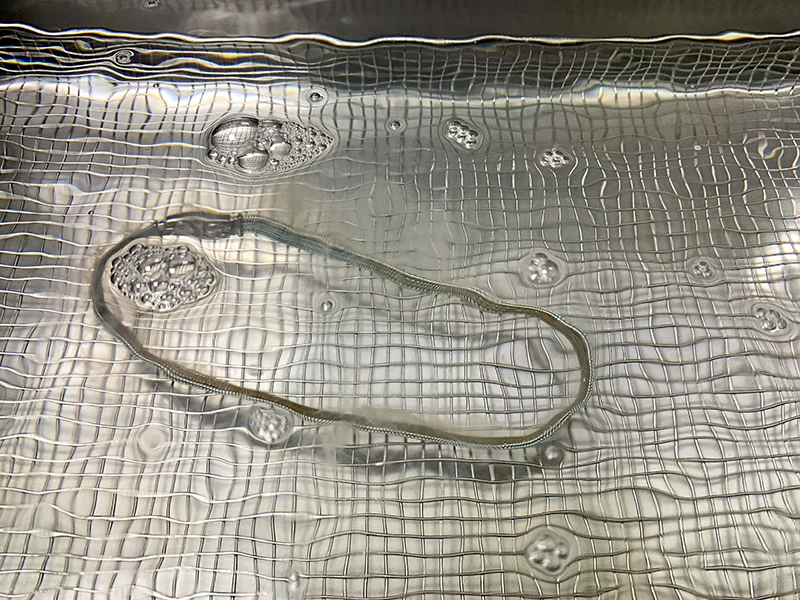

Post process systems and component testing

We can carry out a range of different tests following assembly. These include system leak tests, vacuum testing and electronic testing.