Blog

At OGM, we work with our customers to achieve the best outcome from our products and services. Our team of injection moulding specialists have gathered all relevant information for you in this section.

- All

- 3D Printing

- Assembly

- Basics of Moulding

- Box Build Assembly

- Component Assembly

- Conformal Cooling

- Design for Injection Moulding

- Medical Injection Moulding

- Metal Additive Manufacturing

- Mould Tools

- Moulding Machine

- Plastic Injection Manufacturing

- Plastic Injection Moulding

- Plastic Injection Moulding Company

- Process

- Prototyping

- Rapid Production

- Tooling

- UK Plastic Injection Moulders

Bringing a new medical device to market – the benefits of experience

Bringing medical devices to market is tough. NeuPulse teamed with OGM for injection moulding expertise, refining design, boosting efficiency and ensuring quality for scalable production ...

Read More →

Common problems and solutions for plastic injection moulded transparent parts

Transparent plastics are durable, lightweight and ideal for optics, medical and automotive uses. Flawless clarity needs expert moulding to tackle unique challenges and ensure superior ...

Read More →

Rapid Tooling Vs Rapid Prototyping for Product Development

Rapid tooling involves quickly creating moulds or dies for fast part production, ideal for short runs or urgent projects, while rapid prototyping focuses on quickly ...

Read More →

Engineering polymers for medical injection moulding

There are many different types of polymers that can be used in the manufacture of medical components. Commodity thermoplastic materials are starting to be replaced ...

Read More →

Injection moulding innovation – high performance materials for medical parts

Injection moulding is at the forefront of medical manufacturing, utilising high performance materials to produce precise an durable medical parts.

Read More →

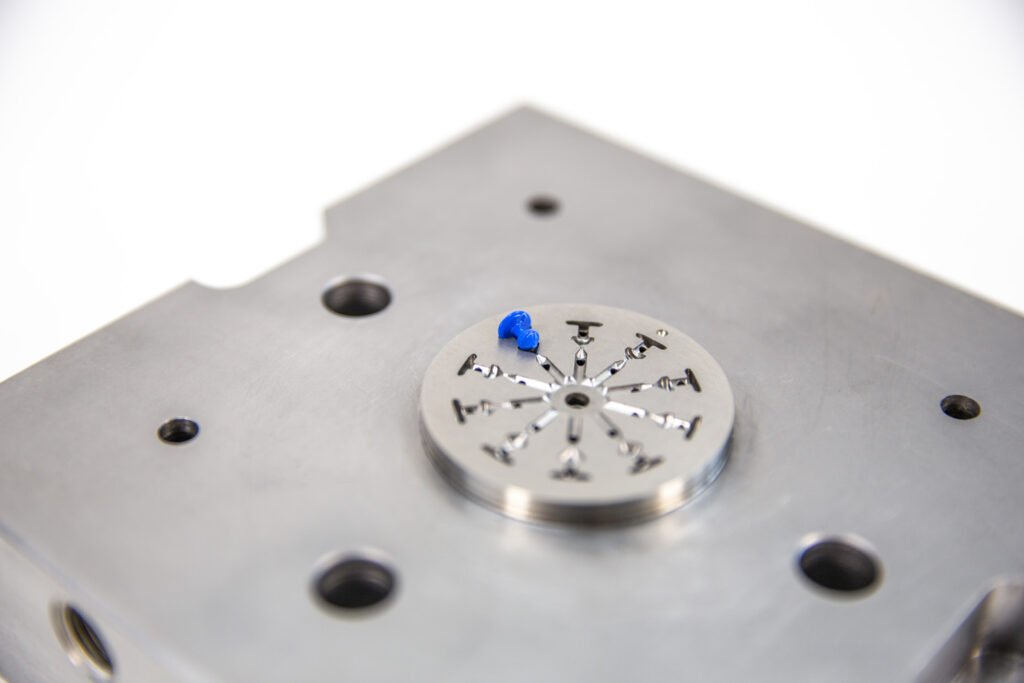

Rapid Tooling in Plastic Injection Moulding and how it differs to Conventional Injection Mould Tooling

Rapid tooling in plastic injection moulding significantly reduces the lead time associated with producing moulds compared to conventional methods. While traditional tooling relies on machined ...

Read More →

The role of rapid tooling in new product development and validation of medical devices and components

Cleanroom injection moulding, combined with rapid tooling significantly enhances the development and validation processes of medical devices and components by ensuring precision and maintaining a ...

Read More →

Investment in people and automation for plastic injection moulding processes can go hand in hand

By embracing both human expertise and automation you can enhance efficiency and innovation in plastic injection moulding.

Read More →