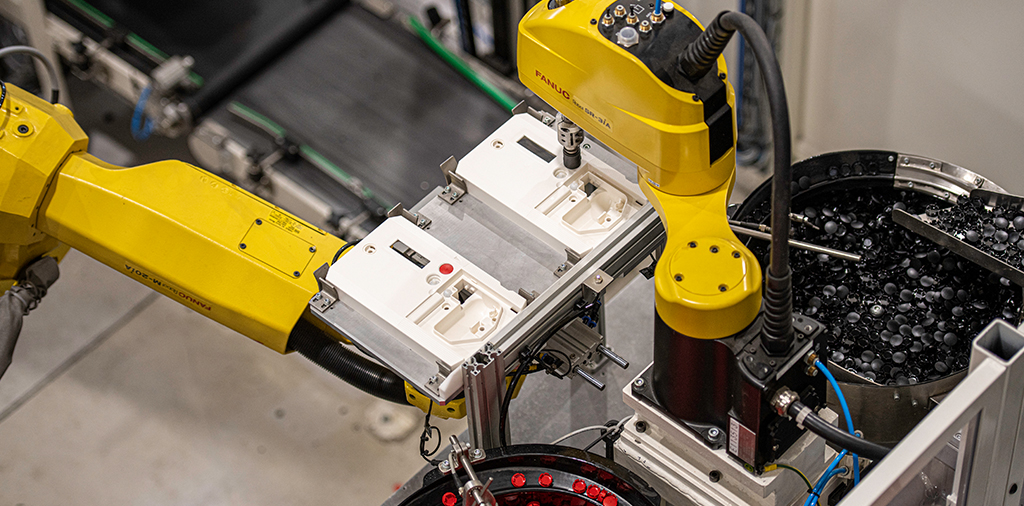

Insert Moulding – specialised plastic injection moulding process

Insert moulding is a plastic injection process where metal, plastic, or electronic components are embedded into moulded parts. It enhances strength, reduces assembly steps, and improves cost-efficiency. Common in automotive, medical, and electronics industries, it enables durable, compact designs while streamlining production and improving overall product performance.

Insert Moulding – specialised plastic injection moulding process Read More »